- Français

- Nederlands

- English

- MenuBack

-

Home

Home - Solutions

- Anticorrosion, metal structures and objectsAnticorrosion, metal structures and objects

- Concrete, walls and exterior facadesConcrete, walls and exterior facades

- Roofs & WaterproofingRoofs & Waterproofing

- Balconies and terracesBalconies and terraces

- Floors: garages, warehouses, technical rooms, parkingsFloors: garages, warehouses, technical rooms, parkings

- Products

- References

- RD Coatings Academy

- Our company

- Our company

- News

- Contact

Delivery 48h

Secure payments

Technical & commercial support

RD-Hydrograff HP Clear Satin

Technical sheetVery resistant clear satin gloss varnish, formulated for long-term protection of surfaces against wear, abrasion, chemical spills, UV rays, and weathering.

RD-Hydrograff HP is the solution for protecting surfaces subjected to harsh conditions. Whether it is a floor, industrial equipment, furniture, etc., RD-Hydrograff HP offers unparalleled performance. For both interior and exterior use! This varnish can be applied directly on most paints or directly on the substrate, depending on the case.

This varnish is also available in matte or high gloss finishes:

RD-Hydrograff HP Clear Mat

RD-Hydrograff HP Clear High Gloss

Since 08/24/2023, online training is required before using this product by professionals. The details can be found in the technical data sheet under the "Safety Data" chapter.

Calculate here the amount of paint needed for your project

Technical sheet

Description of the product

USE:

Highly resistant varnish specially formulated for the long-term protection of surfaces against wear, abrasion, chemical spills, and weathering.

FEATURES:

RD-Hydrograff HP Clear is a two-component aliphatic polyurethane topcoat for indoor and outdoor use. After drying, the coating creates a hard flexible and wear resistant film that can be used for decorative and protective purposes. It is appropriate for application on concrete and wooden floors or objects, walls, steel and non-ferrous metals with a primer, etc. It provides very good resistance against humidity and very good outdoor durability.

RD-Hydrograff HP Clear is water-based, easy to handle and has no fire risks.

RD-Hydrograff HP Clear is formulated with high quality raw materials and provides a very good chemical resistance, a very good resistance against abrasion and solvents, a very high hardness (Taber abrasion: weight loss after 1000 cycles /CS 10 = 0.060 g); while keeping flexibility in its film that will avoid future cracks.

RD-Hydrograff HP Clear can provide very high levels of anti-corrosion protection surpassing traditional three coat systems when combined with RD-Monoguard!

It is also used as transparent anti-corrosion system when combined with RD-Monoguard Clear.

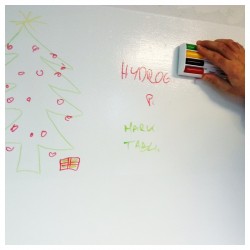

RD-Hydrograff Clear High Gloss can be used as an anti-graffiti protection on top of various kind of surfaces.

SUBSTRATES:

Various surfaces like plastics, concrete, cement, wood, metal, when primed accordingly.

Systems

Floors: concrete, cement, wooden | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Hydrograff HP Clear | 150 / 6 | 60 / 2,4 | 0,15 L / 270 | 1st layer diluted with 10% water if the surface is porous. |

Finish | RD-Hydrograff HP Clear | 150 / 6 | 60 / 2,4 | 0,15 L / 270 | |

TOTAL | 120 / 4,8 | 0,30 L / 135 | |||

Objects, structures in ferrous metal: | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Monoguard | 200 / 8 | 85 / 3,4 | 0,20 L / 200 | Coverage depends on colour contrast. An extra coat may be required |

Finish | RD-Hydrograff HP Clear | 100 / 4 | 40 / 1,6 | 0,10 L / 407 | |

TOTAL | 125 / 5 | ||||

Objects in non-ferrous metal – (stainless steel, aluminium, …), plastic: | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Multiprim | 100 / 4 | 40 / 1,6 | 0,10 L / 400 | Coverage depends on colour contrast. An extra coat may be required |

Finish | RD-Hydrograff HP Clear | 100 / 4 | 40 / 1,6 | 0,10 L / 407 | |

TOTAL | 80 / 3,2 | ||||

Walls, objects and equipment made of wood, concrete, hard plastic: | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Hydrograff HP Clear | 100 / 4 | 40 / 1,6 | 0,10 L / 407 | |

Finish | RD-Hydrograff HP Clear | 100 / 4 | 40 / 1,6 | 0,10 L / 407 | |

TOTAL | 80 / 3,2 | 0,20 L / 200 | |||

Indicated consumption is based on RD-Hydrograff HP Clear High Gloss version and is theoretical, it does not consider potential losses during application. It can also be influenced by the porosity of the substrate. This consumption may not be exceeded. An excessive consumption can cause formation of gas bubbles in the paint film.

Application instructions

APPLICATION CONDITIONS:

Ambient temperature: minimum 10° C (50°F) – Optimal between 12° and 25°C (54° and 77°F).

Relative humidity: maximum 80 %

Dew point > 3°C (5°F)

Screeds may not contain more than 4% of humidity.

APPLICATION MEANS:

Brush and roller.

Compressed air: nozzle opening 1,4 mm – 4 to 6 bars of pressure (60 to 90 psi)

Airless: nozzle opening 007 to 009 – Pressure +/- 70 bars (+/- 1000 psi)

PREPARATION OF THE SUBSTRATE:

Preparation will depend on the kind of substrate. In general, the surface must be cleaned and degreased prior to applying RD-Hydrograff HP Clear.

MIXING RATIO:

Just before the application, add slowly component B into component A by mixing mechanically.

After mixing, let it rest during 5 to 10 minutes so that the air bubbles disappear. The mixture must be used within 2 hours.

Weight: 170 g of component B for 850 g of component A

Volume: 5,5 : 1

POT-LIFE:

2 hours at 20°C

DILUTION:

Dilute the first coat by maximum 10% with water when applied as primer on a porous substrate.

DRYING TIME (20°C - 68°F):

Touch dry: 6 hours

Recoatable: min. 8 hours and maximum 72h without sanding

Resistance to moderate use: 3 days

Resistance to intensive use: 7 days

CLEANING OF TOOLS:

Water

SPECIFICITIES:

Mix well before use.

Technical data

FINISH (Gardner 60°):

Satin: 35 % +/- 5

COLOURS:

Transparent.

DENSITY:

1.02 +/- 0.05 g/cm³

SOLIDS CONTENT:

In weight: 43 % +/-2

In volume: 41 % +/-2

VISCOSITY:

15 - 25 P (Brookfield 20RPM)

VOC CONTENT:

< 20 g/L

FLASH POINT:

Not flammable

STORAGE:

24 months, keep away from frost and store away from heat.

Norms and tests

ABRASION RESISTANCE TABER | ASTM D4060 |

OVERALL MIGRATION | EN 1186 |

QUV | ASTM D4587 / ASTM G53 /ISO11507 |

CORROSION | ASTM B117 / ISO 9227 |

PENCIL HARDNESS | ISO 15184 |

PERSOZ HARDNESS | ISO 1522 |

CHEMICAL RESISTANCE | INTERNAL TESTS |

ADHERENCE CROSS CUT | ISO 2409 |

ISO 16000-6 / VOC Classification in France |

Safety data

The new REACH restriction requires workers handling diisocyanates to undergo training according to their uses. The regulations define 3 levels of training, basic training (level I), intermediate training (level II) and advanced training (level III). The training content has been developed by experts in the field of EHS.

This guide helps you choose the right training. Click here for trainings and guide. Or visit https://www.safeusediisocyanates.eu/

Attention: If you have only chosen the basic training, please note that the advanced training and refresher training mentioned in the REACH restriction in paragraph 74 of annex XVII are not included. In all training courses, the basic training is already included and therefore does not have to be chosen additionally. To register a group of participants, please use an administrative account.

Information related to hygiene and to safety can be found in the Safety Data Sheet available on request.

These specifications are given for information. Since the manufacturer is not able to check the application of the products, he cannot accept any responsibility for it. This technical data sheet replaces all previous editions.

VERS. S045/230217

Very resistant clear satin gloss varnish, formulated for long-term protection of surfaces against wear, abrasion, chemical spills, UV rays, and weathering.