Delivery 48h

Secure payments

Technical & commercial support

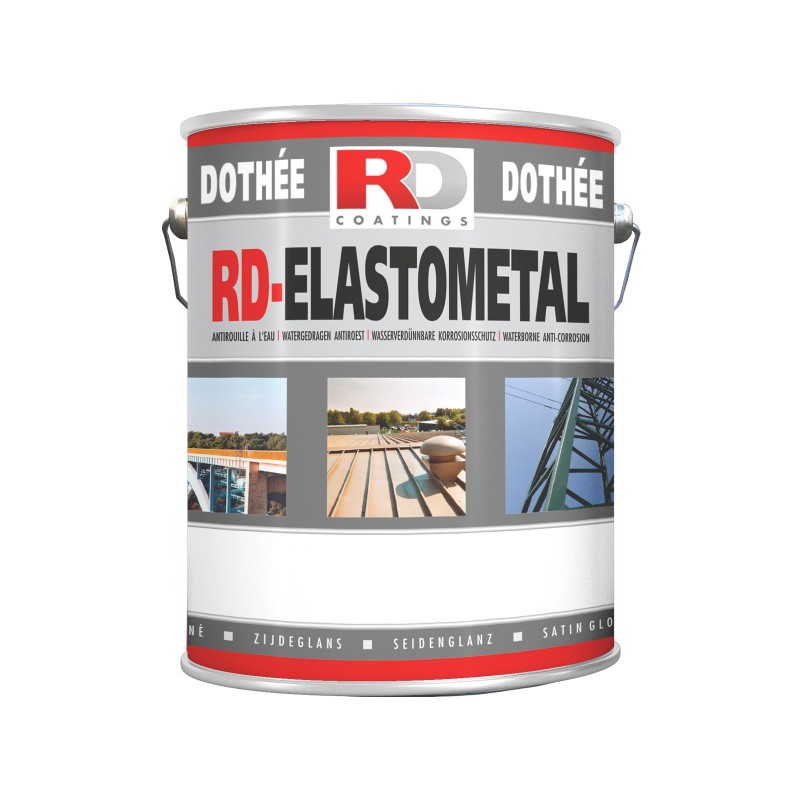

RD-Elastometal

Technical sheetHigh performance elastomeric coating combining superior anti-corrosion and waterproofing properties.

• Waterproofing + corrosion protection, in one single product. A landmark in the renovation of metal roofs.

• Suitable for harsh industrial and marine conditions.

• Lasting flexibility (>200% elasticity).

• Primer and top coat in one, UV and weathering resistant.

• Excellent waterproofing and anti-corrosion properties.

• Unbeatable price/performance.

• Fast and simple application.

Excellent proven technology for the renovation of metal roofs and structures, including many bridges, in mild and harsh environments. RD-Elastometal is a highly reliable coating system that is protecting millions of square meters of metal roofs worldwide.

Its unique elasticity ensures that the coating remains intact in regions that experience broad and frequent temperature changes, preventing the development of film defects.

Many contractors across various industries prefer RD-Elastometal as their go-to coating system due to its simple surface preparation requirements, high tolerance during application, and consistent high performance.